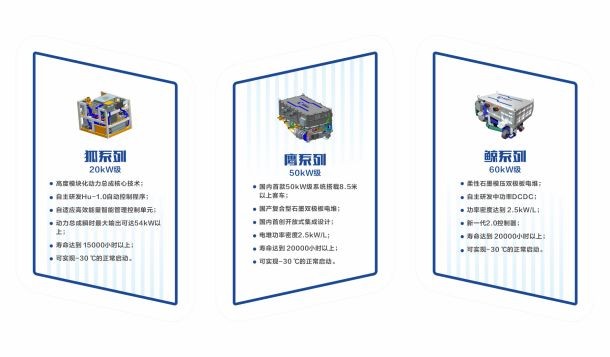

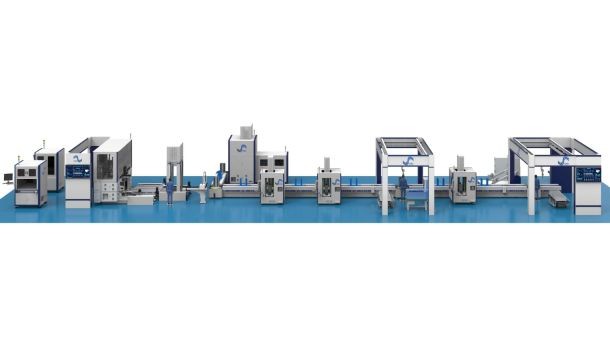

Based on the product development process of the "V Model", the Hydrogen Blue Era has six core product series: Fox, Eagle, Whale, Peng, Kun and Qilin, which have long life, economy, high reliability, high safety, good environmental adaptability and Core product competitiveness such as rapid iteration can be widely used in the commercial vehicle market.

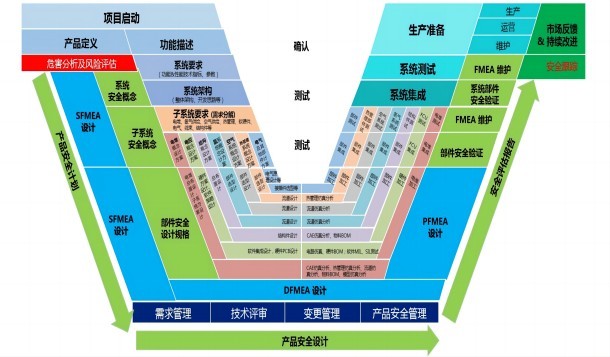

System safety concept, subsystem safety concept, component safety, design specifications, forward product development process based on "V model".

Testing, system integration, system components, security concepts (overall architecture, development methods, etc.), security verification, subsystem requirements (requirements decomposition), product security design, system requirements

System test

FMEA maintenance

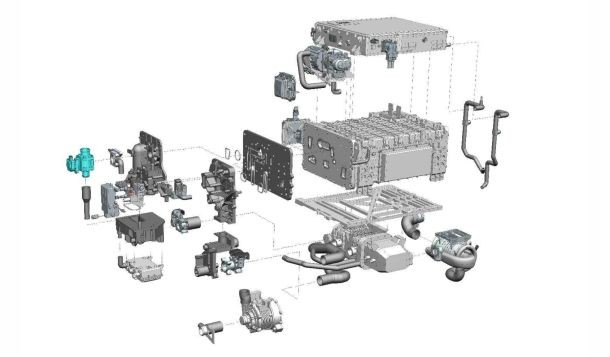

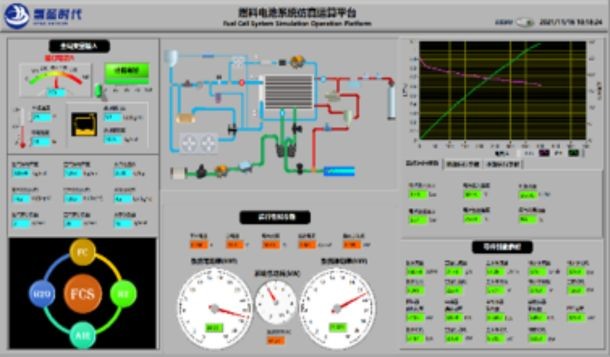

(Technical indicators, parameters) system, system architecture, test system integration, system components, safety concept

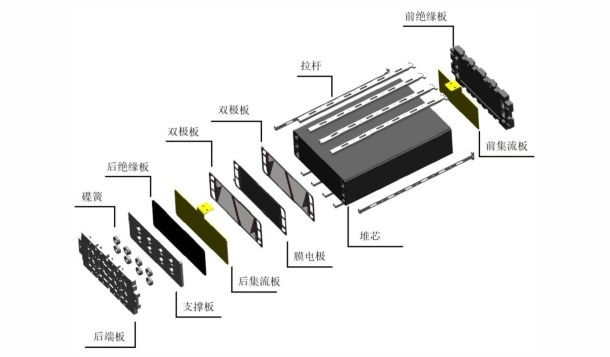

(Overall architecture, development pipeline, etc.) Safety verification subsystem requirements (demand decomposition) Membrane electrode leveling design. Thermal management

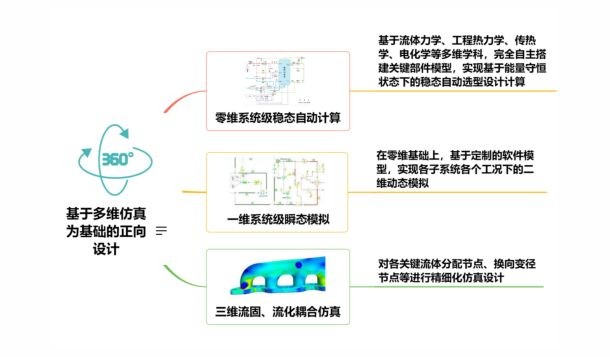

Cr classic analysis. Thermal management simulation analysis, flow channel imitation, structural design, electrical design, etc.

Demand management, technical review, change management, product safety management, CAE simulation analysis, thermal management simulation analysis, flow channel simulation analysis, material BOM, model simulation analysis, stack plate design, membrane electrode selection design, thermal management flow channel , structural design, electrical design, etc.; software integration design, hardware PCB design; circuit simulation, hardware BOM; software MIL, SIL testing; structural component design; CAE simulation analysis, material BOM; runner design; runner simulation analysis; product safety plan.

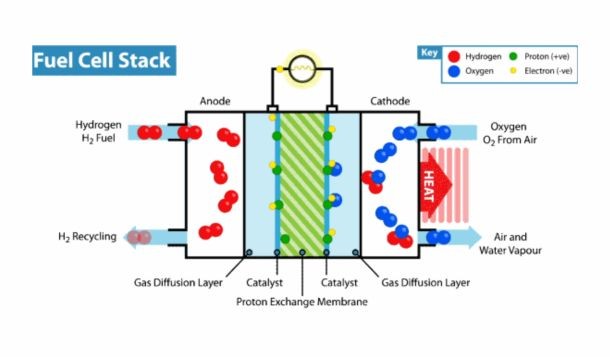

?